Although it may seem simple, entering food analysis results requires constant attention to ensure data accuracy, as the slightest mistake can have major consequences.

Sommaire :

1) The central role of the QHSE Manager in managing food analyses.

2) The pitfalls of manual entry

3) How to eliminate manual entry of results ?

In Food industry, the QHSE (Quality, Hygiene, Safety, and Environment) Manager is a key player. They are responsible for protecting assets and people, ensuring strict adherence to hygiene standards, and promoting a sustainable development approach (CSR) within the organization. However, their primary mission is to guarantee the Food safety to protect consumers.

The central role of the QHSE Manager in managing food testing.

The management of food control analyses is one of the key elements to ensure the food safety of products. In the vast majority of SMEs in the agri-food sector, it is also a responsibility assumed by the QHSE manager.

First and foremost, one must be able to organize and know:

- What needs to be controlled

- Which analyses and methods to choose

- Select partner laboratories

But it is also necessary to retrieve, compile, classify, and record, often in multiple spreadsheets, all the analysis results received each year!

Of course, beyond the other steps that can be "relatively" set in spreadsheets, entering the results stands out as an essential phase but: long, tedious, and let's face it: with little added value!

The pitfalls of manual entry

Manual entry of analysis results, although it may seem basic, has a profound impact on the efficiency of quality control management.

Beyond the considerable time it consumes, it's a source of challenges, stress, and even hidden costs:

Data entry errors

Even minor data entry errors can have significant consequences on:

- Manufacturing (formulation errors, production delays)

- Product releases (delays, or worse: delivery of non-compliant products!)

Traceability of results

With manual entry, it's challenging to trace the origin of an error or modification without having to search for and open the original analysis report. Indeed, without an effective traceability system, it becomes complicated to quickly identify the source of an error or modification and the person who entered the results.

Data dispersion across different mediums

Whether it's spreadsheets, document databases, or handwritten notes, "multi-medium" management makes the overall analysis of results and decision-making very complicated. This fragmentation of information hinders a clear and unified view of trends for product and raw material quality, as well as suppliers and manufacturing processes, etc.

Underutilization of control data

Without suitable tools to centralize and efficiently manage analyses and results, many QHSE managers find themselves forced to often enter "compliant, non-compliant" type results without being able to delve deeper into the entry and especially the exploitation. For instance, screenings for phthalates, dioxins, pesticides contain many molecules that are very rarely exploited!

Would you be able to know if the LoQ of a particular molecule has changed in recent months? Do you know if it was part of the screening last year? Could you cross-reference the molecule in question across different products?

We've all had to open dozens of PDF analysis reports to search for this information, sometimes even during an audit! 😬

Fatigue!

The constant repetition of manual entry can also lead to fatigue and a drop in vigilance, and this last point is dangerous ! This repetitive and monotonous task can obviously lead to error risks because the focus is more on the volume of data to be entered than on the detailed interpretation of results and specifications.

Moreover, this task is discouraging given the range of issues that QHSE Managers must handle, so unfortunately, results are sometimes entered too quickly or too late!

How to eliminate manual entry of results ?

Ending manual entry of results is now possible thanks to CIKLab!

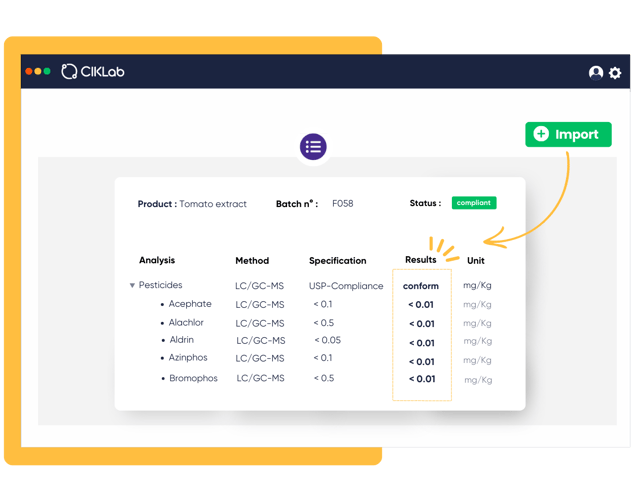

Our application dedicated to the management of food safety testing is designed to meet the specific needs of QHSE managers. It allows, from a simple export of results from your subcontractors, to automatically record analysis results in a control management database.

The results are entered directly for each batch, for each analysis and laboratory!

⚡ You can say goodbye to data entry errors and hours spent inputting data across different mediums!

This means you will:

- Save time

- Import all control data (including the 600 pesticide residues from your screenings)

- Improve traceability

- More easily utilize all your results on a single interface!