In the food industry, efficient operations management is crucial to guaranteeing product quality and safety. ERP (Enterprise Resource Planning) may seem like the ideal solution for centralizing and optimizing processes, but is it really?

When it comes to managing food quality control, traditional ERPs quickly show their limitations. This article explores how to choose a food industry ERP and why a specialized solution like CIKLab is essential for surveillance plans and periodic contaminant analyses.

The challenges of food quality control

Why is quality control crucial ?

Quality control in the food industry goes beyond ensuring consumer satisfaction. It’s about protecting public health by making sure products are free from chemical and microbiological contaminants. Even a small lapse in this process can lead to serious consequences, such as product recalls, regulatory penalties, and damage to the company’s reputation.

The challenges of contaminant monitoring plans

One of the main challenges in food quality control lies in the regular monitoring of contaminants. This involves setting up periodic surveillance plans, often outsourced to specialized laboratories. Managing these periodic analyses presents specific challenges:

-

- Coordination and Traceability: Tracking the sending and receiving of samples, as well as maintaining the traceability of results, is complex.

- Data Analysis: Interpreting analysis results to make informed decisions requires specialized tools.

- Regulatory Compliance: Ensuring adherence to current standards and regulations demands constant vigilance.

The limitations of traditional ERP systems

Why is ERP not enough for food quality control ?

An ERP is designed to integrate and automate business management processes. However, when it comes to food quality control, these systems quickly reveal their limitations:

- Lack of Specialization: General ERP systems are not built to handle the specific requirements of food quality control, such as managing samples and contaminant analyses.

- Data Integration: ERPs can struggle to integrate and analyze data from external laboratories.

- Responsiveness: The necessary responsiveness to quickly process and react to contaminant analysis results is not always guaranteed by traditional ERPs.

Example of limitation: managing periodic analyses

Let’s take the example of managing periodic contaminant analyses. An ERP can help with task scheduling and process tracking, but it typically lacks the necessary features to:

- Sample Tracking: Efficiently manage the sending and receiving of samples.

- Result Analysis: Directly integrate laboratory results and analyze them in real-time.

- Traceability and Compliance: Ensure complete traceability and compliance with standards like HACCP, ISO, etc.

CIKLab: the specific solution for food quality control

What is CIKLab ?

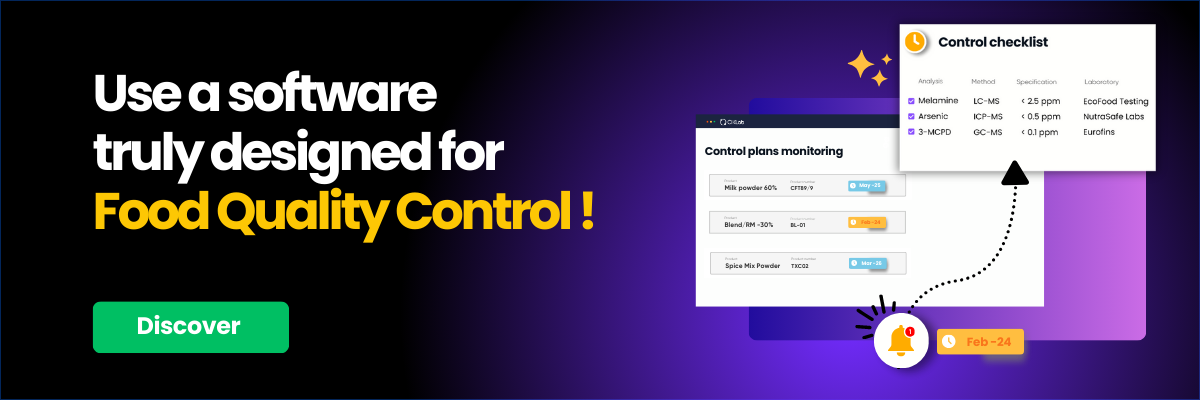

CIKLab is a solution dedicated to quality control in the food industry. Unlike traditional ERPs, CIKLab is specifically designed to meet the unique needs of the food industry for contaminant monitoring and periodic analysis management.

The benefits of CIKLab

- Specialization: CIKLab is designed to manage the specific needs of food quality control, including sample management and contaminant analyses.

- Data Integration: CIKLab enables seamless integration of external laboratory results, with advanced analysis tools.

- Responsiveness and Compliance: CIKLab ensures complete traceability and optimal responsiveness to guarantee compliance with current standards.

Why choose CIKLab ?

By choosing CIKLab, food industry companies can benefit from a specialized solution that:

- Enhances Efficiency: By automating and optimizing quality control processes, CIKLab improves operational efficiency.

- Strengthens Safety: By ensuring rigorous monitoring of contaminants, CIKLab enhances product safety.

- Eases Compliance: By providing complete traceability and proactive management of analyses, CIKLab simplifies regulatory compliance.

Conclusion

Choosing the right ERP for a food company is a strategic decision.

However, when it comes to managing quality control and contaminant monitoring plans, a specialized solution like CIKLab is indispensable. By providing specific expertise and functionality, CIKLab overcomes the unique challenges of food quality control, ensuring product safety and compliance.