Summary

1) What are the common software solutions for managing food quality control ?

2) CIKLab, the software designed by quality control managers!

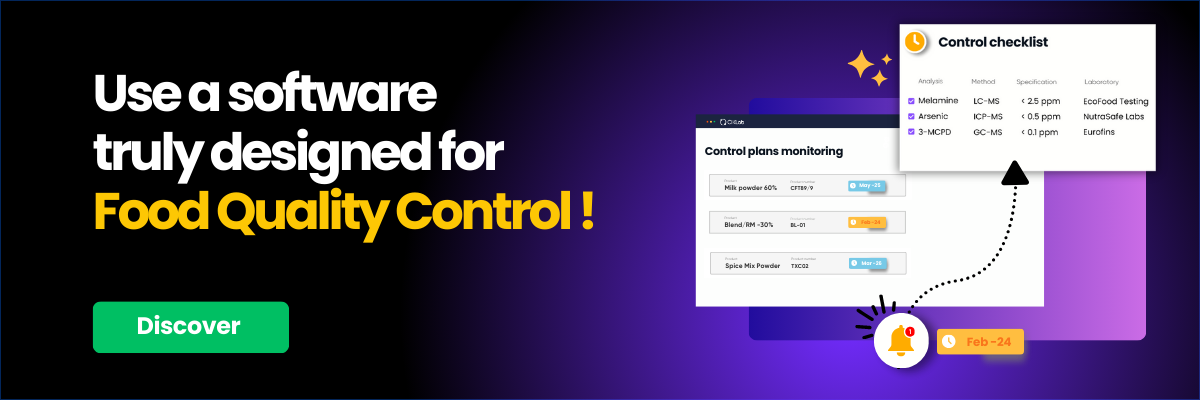

3) What are the specific features of CIKLab ?

4) Use CIKLab to effortlessly manage food quality control !

Managing outsourced testing in the food industry is complex. Specialized laboratories play crucial role in ensuring the quality and safety of food products. However, coordinating these external analyses can be very challenging, especially when using generic software solutions that aren't specifically tailored for this task.

What are the common software solutions for managing food quality control ?

There are various categories of software solutions that address different aspects of food quality control, each with varying degrees of industry-specific features. Among the most common are ERP (Enterprise Resource Planning) systems.

ERPs are essential for food industry companies because they offer integrated management of inventory, traceability, and production. However, they often fall short when it comes to managing outsourced analyses and external analytical data. LIMS (Laboratory Information Management Systems), while extremely powerful for internal laboratories, do not manage external analyses effectively and lack flexibility for periodic monitoring plans. PLM (Product Lifecycle Management) systems focus on product lifecycle management, facilitating collaboration between departments, but do not fully meet the specific needs of routine quality control. MES (Manufacturing Execution Systems) provide real-time visibility into production but are limited in managing the analytical aspects of quality control. ELNs (Electronic Laboratory Notebooks) are excellent for managing R&D activities but are insufficient for the comprehensive management of quality control plans.

Finally, Microsoft Excel remains the most commonly used solution for quality control management due to its flexibility and low cost. However, its limitations include handling large volumes of data, security, collaboration, and automation.

What are the challenges with traditional solutions ?

a) Data fragmentation: Using different software solutions to manage internal and external analyses can lead to data fragmentation. Essential information may be scattered across various systems, making it difficult to centralize and quickly retrieve relevant data. This can result in errors, delays, and inefficient decision-making.

b) Lack of visibility: Another challenge is the lack of real-time visibility into the status of outsourced analyses. Traditional, generic software solutions often do not provide optimal updates and visibility on the progress of analyses, which can delay critical decision-making and compromise responsiveness to quality issues.

c) Lack of specificity: Traditional software solutions often lack features designed to effectively manage external analyses in the food industry. Most generic solutions do not, for instance, account for the specific needs related to external laboratory catalogs, available analyses, control methods, laboratory accreditation, periodic control plans, and more.

CIKLab, the software designed by quality control managers!

CIKLab stands out from other software solutions with one major distinction:

its ability to cater to both internal and EXTERNAL quality control.

Critical analyses for food safety are predominantly outsourced to specialized laboratories, and CIKLab is specifically designed to manage these processes efficiently!

What are the specific features of CIKLab ?

a) Centralized Management of Laboratory Catalogs and Analyses: CIKLab provides a unified platform to access detailed information about available subcontracted laboratories and the analyses they offer. Quality managers can easily review the expertise and accreditations of external laboratories, enabling them to build highly precise control plans that account for laboratories, analyses, and methods.

b) Periodic control plans: In the food industry, periodic control plans or surveillance plans are crucial, often covering food safety checks (pesticides, mycotoxins, heavy metals, ETO, etc.) derived from risk assessments. CIKLab simplifies the planning and management of these periodic controls by ensuring that analyses are performed according to the required frequencies and that results are properly archived. The application includes various alerts to assist users throughout the process.

c) Easy Ordering of External Analyses for Each Batch: With CIKLab, Quality managers can effortlessly place orders for analyses with multiple subcontracted laboratories. Information about samples and analyses is organized into purchase orders and can also be sent directly to the relevant laboratories, reducing the risk of errors and delays.

d) Quick Access to Analysis Histories: CIKLab allows users to quickly and easily access the complete history of analyses, whether internal or outsourced. This feature is invaluable for evaluating trends, identifying potential non-conformities, and making clear, timely decisions.

e) Automatic Generation of COAs (Certificates of Analysis) and Specification Sheets: Certificates of Analysis (COAs) and specification sheets are documents used daily by quality control departments. CIKLab automates the generation of COAs and specification sheets by using analysis results directly stored and managed within the application. This reduces processing time and minimizes the risk of human error during the creation of these documents.

Use CIKLab to effortlessly manage food quality control !

In the complex world of managing outsourced testing in the food industry, choosing the right software solution is essential. CIKLab offers a pragmatic approach, perfectly suited for the daily management of quality control and analytical outsourcing. Its centralized management of laboratory catalogs, periodic control plans, ordering features, and automated document generation make CIKLab the go-to solution for quality managers in the food industry.

By choosing CIKLab, Quality managers can efficiently manage outsourced analyses, enhance the quality and safety of their food products, and optimize their operational efficiency.

©2024 CIKLab.com All rights reserved.