The food industry is a highly sensitive sector that requires constant attention to quality control to ensure food safety.

.png?width=480&height=320&name=Design%20sans%20titre%20(7).png)

Summary :

1) Outsourcing control analysis

2) Your third-party laboratories are a valuable resource

3) Why is outsourcing analysis difficult ?

There is an array of texts and regulations that govern food safety, including the hygiene package. Implemented in 2006, its objective is to harmonize practices at the European level by involving all actors in the food chain. This set of texts imposes a results-based obligation on all parties and the implementation of a risk management system often based on the HACCP method.

Recent food crises such as fipronil, ethylene oxide, or last year's Escherichia coli (STEC) contaminations consistently highlight the importance of control analyses.

"Analytical monitoring is an obligation [...] which contributes to food safety".

DGAL/MUS/2023-11 du 10/01/2023

Outsourcing control analysis

All Food industries outsource part or all of their control analyses to subcontracted laboratories.

Quality departments have faced an increase in controls and a wider variety of analyses in recent years.

Why?

- Regulations and scientific opinions evolve rapidly because analytical techniques allow for the quantification of an increasing number of different food pollutants and contaminants.

- Export controls are becoming more stringent.

- "Food Fraud" and "Food Defense" require the consideration of new types of risks and hazards. Customers and consumers increasingly demand transparency and evidence.

Very few industrial players are capable of conducting all these controls on their own; they all rely on specialized laboratories.

Your third-party laboratories are a valuable resource !

Your network of subcontracted laboratories is an integral part of your control policy. It is often observed among industrial companies that the outsourcing step is perceived as disconnected from the existing control systems.

Build and animate your network of laboratories!

It is crucial ! Your network of subcontractors is a valuable resource :

- Technical expertise : Identify and select specialized service providers in each field.

- Regulatory expertise : Access support and guidance on regulatory matters.

- Assistance with specific challenges : Seek assistance for issues such as identifying the source of contamination.

For the sake of simplicity, many companies choose to work with one or two generalist laboratories, but it is a missed opportunity to not leverage a network of experts!

What benefits are there?

Demonstrate that you are not solely in control and that you have a strong grasp of your system and risks : you have the ability to take action or mobilize resources when faced with regulatory changes, new inspections, or hazards.

- Increase the comparison between laboratories to further support your results and level of assurance.

- It is also an interesting choice to consider for reducing control costs, shortening timelines, etc.

💡 Outsourcing should not be an additional step but an integral part of your quality control process.

Why is outsourcing analysis difficult ?

It is often the "dark side" of control services, in the sense that few people in organizations understand how complex it can be!

Firstly, it is necessary to identify the necessary analyses and laboratories. Secondly, subcontracting management is often disconnected from existing systems, including ERP, LIMS, and everyone uses Excel files to manage this activity. Thirdly, each laboratory has different order support methods (customer portal, Excel file, signed quote, in-house purchase order form to fill out). Lastly, the tracking of ongoing analyses is burdensome to complete and maintain.

You have to create your own catalogue of analyses and set up your own network of laboratories.

Control analysis is a specialized market (microbiology, contaminants, nutritional analysis), which implies that the offering is very broad and many laboratories specialize in specific areas.

Firstly, it is necessary to identify the required analyses, but in what context? (Routine, need for expertise+++) What methods should be chosen? Is it suitable for my product? Secondly, it is necessary to reference laboratories capable of conducting these analyses, but what are the expected levels of reliability for each analysis and each laboratory? Should we choose "only" an ISO 17025 accredited laboratory, or an analysis test under accreditation ?

You need to plan your tests and order your analyses for each laboratory!

It becomes increasingly challenging because we are delving into the daily operations and managing multiple dimensions for control.

The required analyses depend on the batches and therefore the matrices. For example, microbiology methods can vary significantly between dairy products and herbal infusions. As we have seen, it is necessary to choose the appropriate laboratory for each analysis and then place orders for external analyses based on each laboratory's requirements. For an increasing number of laboratories, orders must be placed through online customer portals, while others use Excel files or require signed quotations.

Such ordering methods might be understandable if analyses were conducted occasionally, but it is no longer feasible for routine operations.

It is extremely difficult to incorporate all dimensions—laboratories, analyses, methods, matrices—and further integrate periodic or non-periodic analysis planning into a single control system.

All analyses must be monitored!

The questions are simple: what analyses are being run? And when will I get the results? Once again, you have to set up yet another Excel file for this purpose.

So, no, it may not be obvious at first glance, but outsourcing your analyses is complex and time-consuming! Put end to end, all these steps can take up to 10 hours a week...

💡 At CIKLab, we pretend to believe that this follow-up and logistics are not the added value of a quality control service!

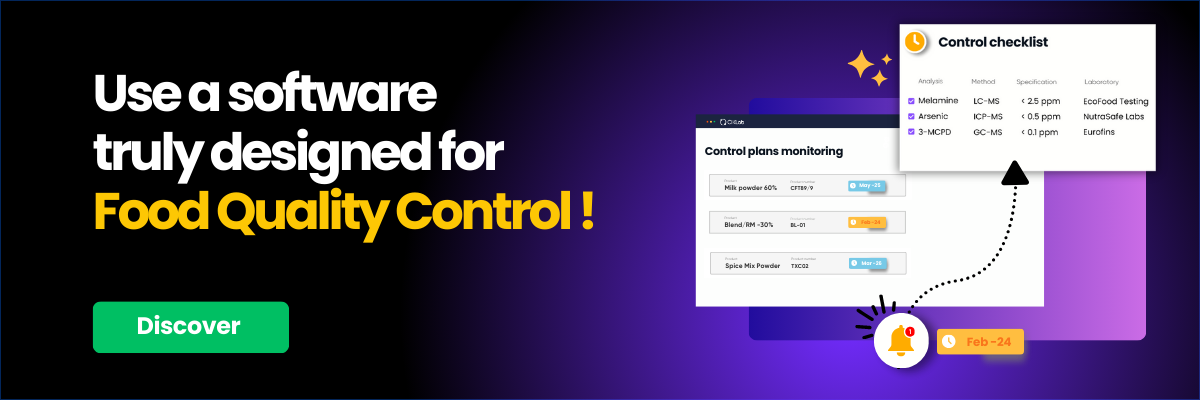

How can CIKLab help you ?

CIKLab will enable you to create a dynamic system around analytical subcontracting.

📌 Easily reference your analyses and laboratories!

With CIKLab, you can build a centralized and shared database of laboratories. This database is fully customizable, allowing you to enter all the necessary details for each analysis, including methods, techniques, pricing, and turnaround time. You have complete control over which laboratories are allocated to each analysis.

💡 Reference as many laboratories as possible in different disciplines to demonstrate your ability to meet any requirement and have backup labs in case of issues.

🖱️ Click and order!

With CIKLab, every time you create a batch, the analyses, methods, and laboratories are already registered, and your controls are scheduled!

CIKLab automates:

- Launching analyses based on the specified method, control periodicities, and allocated laboratories. The expected specifications for each control are set in advance.

💡 With just one click, you can automatically generate purchase orders and identification labels for each subcontractor.

👀 Simplify tracking all your controls

No more need for another tracking file—everything is linked with CIKLab.

The application can automatically calculate your deadlines, providing you with an overview and excellent visibility on:

💡 The deadlines of ongoing analyses in each laboratory for each batch!

©2024 ciklab.com All rights reserved.