Starting in April 2024, version 5.1 of FSSC 22000 will be officially replaced by the new version FSSC 22000 V6.

Among the new requirements, a new chapter " 2.5.9 Quality Control " has been introduced. It is interesting to note that in this chapter, the concept of quality control is not only related to food safety but also encompasses broader "quality" criteria, and CIKLab handles it very well!

Sommaire

2) FSSC 22000 V6: What has changed ?

3) FSSC 22000 V6: What are the new requirements ?

4) Understanding Chapter 2.5.9 of FSSC 22000 V6

5) Meeting the Requirements of FSSC 22000 2.5.9 with Quality Control Software?

6) How to implement the requirements of clause 2.5.9 of FSSC 22000 with CIKLab.

What is FSSC 22000?

FSSC 22000 (Food Safety Systems Certification) is a certification scheme that primarily relies on the ISO 22000 standard but also combines sector-specific prerequisites (such as ISO/TS 22002-1 for food manufacturing) and additional requirements from FSSC itself.

This standard is internationally recognized by the GFSI (Global Food Safety Initiative) and is designed to ensure food safety throughout the supply chain. This recognition gives FSSC 22000 credibility and worldwide acceptance among retailers, manufacturers, and food product suppliers.

Key components of FSSC 22000 :

- ISO 22000 : International standard that defines the requirements for a food safety management system.

- ISO/TS 22002-1 (or other sector-specific PRP): Technical specifications for prerequisites necessary for food safety.

- Additional FSSC requirements: Specific additional requirements for FSSC 22000, such as service management, Food Defense, and Food Fraud.

What is the difference between ISO 22000 and FSSC 22000?

Fundamentally, ISO 22000 is a technical standard for food safety management that is not recognized by the GFSI, whereas FSSC 22000 is a certification scheme that incorporates this standard and is recognized by the GFSI.

FSSC 22000 V6: What has changed ?

Version 6 of FSSC 22000 was published in April 2023.

Here are the main reasons for the transition from version 5.1 to 6:

Integration of ISO 22003-1:2022 requirements:

One of the primary drivers for this update is the incorporation of ISO 22003-1:2022 requirements. This standard provides guidelines for the audit and certification of food safety management systems. By integrating these new requirements, FSSC 22000 version 6.0 improves the consistency and effectiveness of audits, ensuring better alignment with international standards.

Strengthening requirements to help organizations achieve the United Nations Sustainable Development Goals (SDGs):

FSSC 22000 version 6.0 places particular emphasis on organizations' contributions to the UN SDGs. Specific requirements have been introduced to encourage companies to adopt sustainable practices, such as reducing food loss and waste and improving resource management. These measures aim to promote a more sustainable and responsible food supply chain.

Integration of feedback from the survey on the development of version 6.

FSSC 22000 V6: What are the new requirements ?

In addition to numerous themes and reinforcements added to the existing requirements, V6 incorporates new chapters:

2.5.15 Equipment Management (Hygienic Design)

This section addresses equipment management with a focus on hygienic design.- Documented purchase specification: Equipment must meet hygienic design criteria, legal requirements, and client needs.

- Risk-based change management process: For new equipment or modifications to existing equipment, a risk management process must be documented, including proof of successful commissioning.

- Appropriate controls: To ensure equipment does not compromise food safety, specific controls and measures must be implemented and maintained.

2.5.16 Food Loss and Waste

This section aims to reduce food loss and waste within the organization and supply chain:- Documented policy and objectives: Organizations must define a strategy to reduce food loss and waste.

- Controls for donated products or those intended for animal feed: Ensure these products are safe for consumption.

- Legal compliance: All processes must comply with applicable legislation and not compromise food safety.

2.5.17 Communication Requirements

Communication requirements include:- Notification of major events: The organization must inform the certification body within 3 business days of any major event affecting the food safety management system, including natural disasters, public food safety incidents, actions imposed by regulatory authorities, and fraudulent activities.

- Response and emergency preparedness measures: Implement appropriate measures to respond to these situations.

2.5.8 Food Safety and Quality Culture

The focus is on establishing and maintaining a positive culture of food safety and quality:- Documented objectives: Define objectives for the culture of food safety and quality.

- Documented culture plan: Include targets, deadlines, and activities for communication, training, employee engagement, and performance measurement.

- Management review: The objectives and plan must be included in the management review and continuous improvement processes.

2.5.9 Quality Control

Quality control requirements cover several aspects:

- Quality policy and objectives: In addition to the requirements of ISO 22003-1:2022, a quality policy and objectives must be established.

- Product quality parameters: All products or product groups must meet clear and precise "quality" specifications, including control and testing.

- Analysis and evaluation: The results of the quality parameters must be analyzed and evaluated, and included in the management review.

- Quantity control procedures: Ensure that products meet legal and customer requirements for weight and volume.

- Line startup and product change procedures: Control labeling and packaging to avoid errors and ensure compliance.

Understanding Chapter 2.5.9 of FSSC 22000 V6

What does Chapter 2.5.9 of FSSC 22000 say about quality control ?

a. The organization must:

i. In addition to clauses 5.2 and 6.2 of the ISO 22000:2018 standard and in accordance with them, establish, implement, and maintain a quality policy and objectives.

ii. Establish, implement, and maintain quality parameters that comply with finished product specifications for all products and/or product groups within the scope of the certification, including product release, which deals with quality control and testing.

iii. In addition to clauses 9.1 and 9.3 of the ISO 22000:2018 standard and in accordance with them, analyze and evaluate the results of quality control parameters, as defined in point 2.5.9 (a)(ii) above, and include them as inputs for the management review; and

iv. In addition to clause 9.2 of the ISO 22000:2018 standard and in accordance with it, include the quality elements defined in this clause within the scope of the internal audit.

b. Quantity control procedures, including for unit, weight, and volume, must be established and implemented to ensure that products meet legal and customer requirements. They include a calibration and verification program for the equipment used for quality and quantity control.

c. Line startup and product change procedures must be established and implemented to ensure that products, including packaging and labeling, meet legal and customer requirements. Controls must be in place to ensure that labeling and packaging from the previous batch have been removed from the line.

Meeting the Requirements of FSSC 22000 2.5.9 with Quality Control Software?

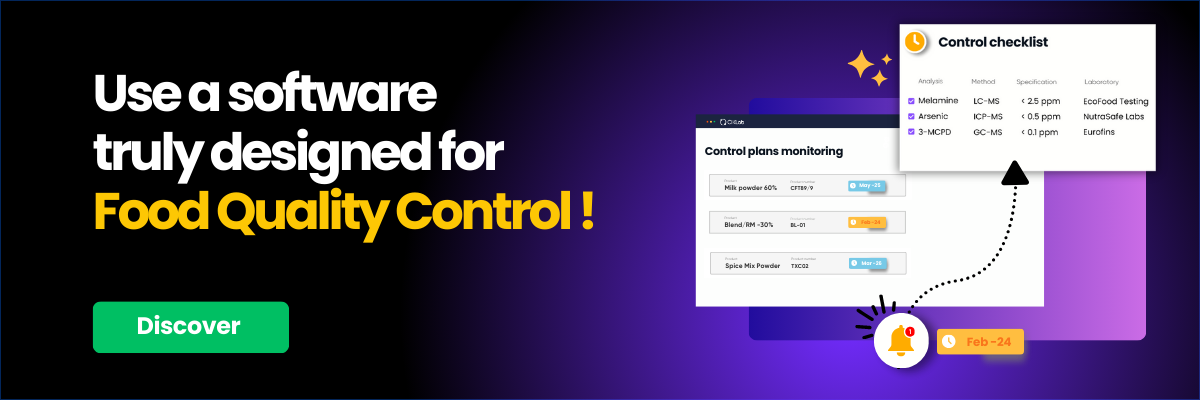

CIKLab is an online application dedicated to food quality control that streamlines and improves your quality control processes in accordance with the strict requirements of FSSC 22000.

With CIKLab, you can centralize all data related to controls, from establishing and maintaining parameters and specifications to conducting analyses and evaluations, and utilizing control results.

Let's take a closer look at the requirements with the FSSC 22000 interpretation guide

|

Interpretation Guide for Chapter 2.5.9 |

|

|

In accordance with clause 2.5.9 (a)(i), the organization must establish, implement, and maintain quality objectives. Objectives are the results the organization aims to achieve. Quality objectives are specific goals related to quality; they are generally based on the organization's quality policy. Quality objectives are also typically specified for relevant functions, levels, and processes within the organization. The organization must define quality objectives that are SMART:

|

CIKLab is a solution focused on managing analytical monitoring and quality control.

|

|

In accordance with clause 2.5.9 (a)(ii), |

CIKLab allows you to :

|

| Quality parameters in this context refer to the quality characteristics associated with the product. To implement this requirement, the organization must:

|

CIKLab offers the ability to centrally and easily manage all control and monitoring plans for each:

|

|

CIKLab enables quality control departments to manage ALL product specifications in a single application. Specifications are automatically updated, and you can receive alerts when control plans need revision. Editing technical sheets and control checklists is automatic !

|

|

CIKLab manages and automates all parameters, enabling the automatic generation of dated and signed documents in a digital library. |

| The quality parameters for all products must be monitored by the organization, which should establish monitoring procedures including the method, frequency of monitoring, responsible person, documented evidence to maintain, actions to take in case of non-conforming results, etc. |

CIKLab integrates for each control plan:

For each lot or batch, CIKLab recalls the entire testing schedule to prevent errors.

|

|

Regarding product release, in addition to relevant food safety parameters, organizations must also have relevant quality parameters used to establish that a product can be released.

|

CIKLab features a workflow with user rights matrices that allow for the validation of test and analysis results and electronic product release. |

|

Although requirement 2.5.9 specifically addresses quality parameters related to finished products, if a raw material impacts the quality of the finished product, the organization must also manage it. The organization must still manage its raw materials in accordance with their specifications as defined under additional requirement 2.5.1 (d) of FSSC 22000, including compliance with raw material quality specifications.

|

CIKLab manages all the company's material control plans, including and especially raw materials! Certain features allow for tracing the results of raw materials to the finished product! (Transfer)

|

|

CoAs (Certificates of Analysis) and CoCs (Certificates of Conformance), including quality parameters, must also be available for marketed and solicited product batches (category FII organizations only). |

CIKLab stores and manages all of your technical documentation as well as that of your suppliers.

|

|

In accordance with clause 2.5.9 (a)(iii), the organization must undertake the analysis and evaluation of the results of quality control parameters, as defined under clause 2.5.9 (a)(ii), and include them as an input for management review.

|

CIKLab records, stores, and secures ALL tests and analysis results in one place The application allows for simple and quick utilization of all control data

In CIKLab, the utilization of reliable control data is the foundation for building control KPIs!

|

|

In accordance with clause 2.5.9 (a)(iv), the organization must include quality elements as defined in clause 2.5.9 within the scope of the internal audit. Therefore, the requirements of clause 9.2 of ISO 22000:2018 apply to this requirement.

|

In CIKLab, all control traceability is easily accessible and secure. Additionally, an audit trail feature allows tracking and timestamping all changes made to control plans, batch management, etc.

|

How to implemente the requirements of clause 2.5.9 of FSSC 22000 with CIKLab.

CIKLab offers major advantages for quickly integrating the requirements of clause 2.5.9 of FSSC 22000 V6.

Firstly, this application centralizes all quality control data, allowing easy maintenance, updating, and management of specifications and control plans for each product.

CIKLab also ensures rigorous management of control parameters such as analyses, specifications, internal or external laboratories through an automated system, significantly reducing the risk of human errors.

CIKLab facilitates the analysis and utilization of quality control results to create KPIs that are truly focused on control.

With CIKLab, you can:

- Centralize, manage, and automate all your control and monitoring plans

- Establish and maintain rigorous management of control parameters and specifications

- Automatically generate all technical documentation, including CoAs

- Simplify the utilization of analysis results.

©2024 CIKLab.com All rights reserved.