Food safety is a cornerstone of the food industry, ensuring that products meet high-quality standards while protecting consumer health. This article explores the daily challenges of quality control in the food sector and how innovative tools like CIKLab can help streamline processes and ensure food safety compliance.

Summary :

1) What are the challenges in food industry quality control?

2) Operational challenges in food quality control management

3) CIKLab: a comprehensive food quality control software

4) Tangible benefits for food industry businesses

5) How CIKLab simplifies food quality control management

What are the challenges in food industry quality control?

Food safety: the ultimate priority through proof!

n the food industry, safety is not optional — it’s essential and must be proven at every stage. Ensuring products are free from contaminants such as chemicals, pathogens, allergens, or foreign objects is critical to protect consumer health. A single failure can have significant consequences:

- Health risks: illness, hospitalizations, and even fatalities.

- Mass product recalls: damaging financially and reputationally.

- Legal actions: including fines and sanctions.

- Reputation damage: trust loss from consumers and partners.

The food industry requires documented proof of compliance at every step — from raw material sourcing to final product delivery — ensuring full traceability and transparency.

Food safety regulations in the food industry

Strict regulatory frameworks govern food safety across regions. In Europe, for example, key regulations include:

- Regulation (EC) No 178/2002 – "Food Law" principles

- Regulation (EC) No 852/2004 – food hygiene standards

- Regulation (EC) No 853/2004 – animal-origin food safety rules

- Regulation (EC) No 183/2005 – animal feed hygiene requirements

- Regulation (EU) 2017/625 – official controls and inspections

- Regulation (EC) No 2073/2005 – microbiological food safety criteria

Compliance requires proactive risk management, including comprehensive control plans, regular audits, and accurate traceability from raw materials to finished products.

Operational challenges in food quality control management

Managing food quality involves several complex steps:

Managing comprehensive control plans

Quality managers must handle extensive testing and monitoring plans, from raw materials to production environments. Each product has specific analysis frequencies, methods, and specifications. Manual management using spreadsheets increases the risk of errors.

Organizing laboratory analyses and batch tracking

Food companies must decide what to test, when, and where. This includes choosing appropriate laboratories, scheduling sample collections, and ensuring complete traceability.

Interpreting data and monitoring batches

Analysis data can quickly pile up, making it hard to interpret trends, detect anomalies, or implement corrective actions. Consolidating reports from multiple sources without proper software can delay decisions.

Managing laboratory partnerships

Many food businesses outsource lab testing. Coordinating these labs requires:

- Scheduling tests and ensuring timely results

- Collecting and integrating test data

- Ensuring laboratory compliance

CIKLab: a comprehensive food quality control software

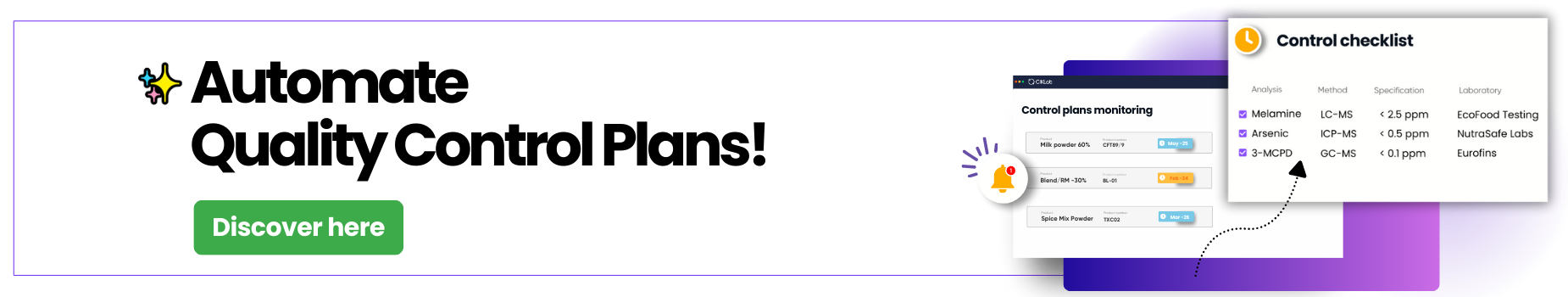

1. Planning and automating controls: boost efficiency

With CIKLab, creating and managing your control plans becomes simple:

- Fast creation: Design your control plans in less than two minutes with an intuitive interface and a predefined analysis catalog.

- Precise configuration: Define control frequencies and link them to your product specifications for flawless execution.

- Automatic notifications: Each new batch comes with automatic alerts for required analyses, ensuring proactive management.

This automation reduces human errors, facilitates team coordination, and accelerates action implementation.

>> Learn more about quality control plan management here

2. Centralized batch and analysis management

CIKLab centralizes all your batch management data on a unique and secure platform. The software automatically guides you through the process for each batch:

- Control plans, results, and documents: Access a complete view of your quality processes anytime, from control plan creation to batch release.

- Real-time monitoring: Track control analysis progress and batch release dates.

- Product history: Quickly consult past analysis results for each product or batch, a valuable feature for audits or investigations.

Centralized management ensures full analytical traceability and simplifies batch validation.

>> Learn more about batch management

3. Importing analysis results: simplified and secure data entry

To avoid data entry errors and speed up data processing, CIKLab offers an automated analysis result import feature:

- Seamless integration: Results from your partner laboratories are directly imported into the system, ensuring accuracy and timely updates.

- Optimized processing: Collected data automatically feeds reports and indicators, reducing delays between result reception and data utilization.

This automation lets you focus on trend analysis and implementing corrective actions.

4. Automatic certificate of analysis (CoA) generation: save time and inspire trust

Manually generating certificates of analysis (CoAs) can be time-consuming and prone to errors. With CIKLab, the process becomes instant:

- Customized certificates: Produce dated, signed documents that comply with your specifications and requirements at each batch validation.

- Efficiency gains: Free up your teams by automating a repetitive task while enhancing the reliability and professionalism of the documents sent to your customers.

CoAs generated by CIKLab are a guarantee of transparency and quality for your clients.

>> Automatically edit certificates of analysis?

5. A secure and accessible SaaS software solution

As a SaaS (Software as a Service) solution, CIKLab is accessible from any device with a secure connection. This flexibility ensures:

- Secure data storage

- Frequent feature updates

- Reduced IT infrastructure costs

- Simplified use for field teams

Tangible benefits for food industry businesses

By leveraging SaaS technology and an interface designed for food industry professionals, CIKLab delivers concrete advantages to support food quality management and compliance.

- Comprehensive management of control and monitoring plans for raw materials and finished products.

- Simplified creation and management of technical data sheets, specifications, and control plans.

- Effective planning and management of periodic controls, with integrated alerts for each new batch.

- Centralized management of laboratory and analysis catalogs, allowing easy access to subcontracted laboratory information and analyses.

- Simplified external analysis ordering for each batch, reducing the risk of errors and delays.

- Streamlined monitoring of ongoing controls, providing better visibility into analysis deadlines.

- Quick access to the full analysis history, facilitating trend evaluation and non-conformity detection.

- Automatic generation of certificates of analysis (CoAs) and specification sheets, reducing processing times and human errors.

How CIKLab simplifies food quality control management

In the food industry, where safety and compliance are non-negotiable, CIKLab simplifies quality control management through:

- Intuitive platform: user-friendly software tailored to food industry professionals.

- Automated quality workflows: from test scheduling to CoA generation.

- Advanced traceability: comprehensive tracking for full transparency.

- Cloud-based accessibility: work from anywhere with secure data storage.

With CIKLab, food industry companies can ensure product safety, maintain regulatory compliance, and achieve operational excellence — through proof!